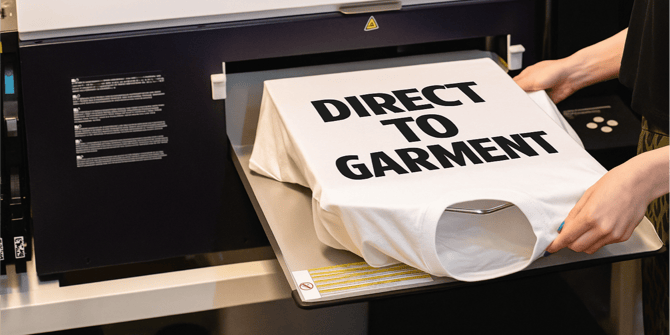

What is Direct to Garment (DTG) Printing?

Printed using the Direct to Garment (DTG) method, this technique allows for intricate details and vibrant colours, making it ideal for graphics, photos, and designs with gradients or multiple shades. With cutting edge digital printing technology, DTG printing produces sharp, long-lasting prints that retain their vibrancy even after repeated washes. This process ensures your designs stand out with remarkable clarity and colour depth.

Tips for Designing for Inkjet Printing

Use high-resolution artwork (minimum 300dpi)

To achieve crisp, professional results, always design or export your artwork at 300dpi at the actual print size. Lower resolutions can lead to pixelation or fuzzy edges, especially in fine detail or photographic elements.

Set your file to CMYK colour mode

Inkjet printers use CMYK (Cyan, Magenta, Yellow, Black) ink, so designing in CMYK helps you preview how colours will appear in print. This minimises surprises and keeps your colours looking accurate.

Flatten your design before exporting

To avoid issues with missing elements or layering errors, flatten your final artwork before saving it as a PDF. This ensures the print file reflects exactly what you see on screen.

Avoid overlapping paths in vector graphics

Overlapping shapes or stacked elements can sometimes cause unpredictable results in digital printing. Where possible, knock out or merge shapes into a single, unified path.

Convert all strokes and text to outlines

Ensure consistency and avoid formatting issues by converting text to outlines and changing any strokes to filled shapes. This locks in your design and prevents anything from dropping out during print processing.

Use vector graphics where possible—but raster is fine too

Inkjet printing can handle both vector and raster images. Vectors are ideal for logos and line art, while high-res raster images work perfectly for photos and complex illustrations. Just be sure everything is sharp and correctly scaled.